Besides the regulatory requirement to have a safety management program, it’s important to prioritize worker safety and health for a number of reasons. All businesses rely on their employees to fuel their success. If workers are injured or become sick on the job, it affects productivity, and ultimately, profitability. With this in mind, here’s an overview of a successful safety program, the elements, and benefits to your business.

What is a successful safety program?

The core purpose of a safety program is to prevent workplace injuries, illnesses, and deaths as well as the suffering and financial hardship these events can cause for workers, their families, and employers. Safety programs communicate standardized procedures for handling potential risks, like using fall protection equipment when working above ground. When management and workers collaborate on these procedures, it creates a safety culture. This culture helps determine the success or failure of the safety program. When employees know that their concerns and suggestions will be heard and that management truly values their safety and health, a positive culture is created where safety is a priority instead of just a box to check.

Creating a successful safety program involves being proactive when it comes to addressing potential risks and hazards. Only reacting after an incident occurs, or when a regulation becomes law, can lead to the potential for more severe injuries and illnesses, along with potential fines from regulatory bodies.

What are the elements of a safety program?

OSHA defines seven core elements of a safety program in the construction, industrial, and manufacturing sectors:

- Management leadership – Management demonstrates its commitment to health and safety by making it a core value, establishing goals and objectives for the program, providing adequate resources and support, and setting a good example.

- Worker participation – All workers are involved in the program, helping to set goals, identify hazards, investigate incidents, and track progress. Communication barriers, like language, are removed or addressed.

- Hazard identification and assessment – An initial assessment of existing hazards is followed by periodic inspections and reassessments to identify new hazards. Identified hazards are prioritized for control.

- Hazard prevention and control – Employers and workers cooperate to choose methods for addressing workplace hazards using engineering solutions first, followed by safe work practices, administrative controls, and finally personal protective equipment (PPE).

- Education and training – All workers are trained in how the program works and what their responsibilities are, including management. Everyone is trained in how to recognize workplace hazards and what control measures have been implemented.

- Evaluation and improvement – The program is continually monitored to verify implementation, identify shortcomings, look for opportunities for improvement, and implement necessary actions.

- Communication and coordination for employers on multiemployer worksites – Communicate the hazards present at the worksite and the hazards that work of contract workers may create on site and coordinating on work planning and scheduling to identify and resolve any conflicts that could impact safety or health.

What are the benefits of a safety program?

Successfully implementing and maintaining a robust safety program ultimately leads to long-term success, both for the employees and the business. Specifically, companies can expect the following benefits:

- Increased productivity and enhanced overall business operations

- Compliance with regulatory requirements

- Lower workers compensation insurance rates

- Engaged employees with an increased sense of purpose and responsibility

- Improved social responsibility

- Reduced or ‘goal zero’ injuries, safety violations, fines, and insurance penalties

With these benefits, and the knowledge that you are doing the right thing, a safety program is a must for all businesses, no matter the industry.

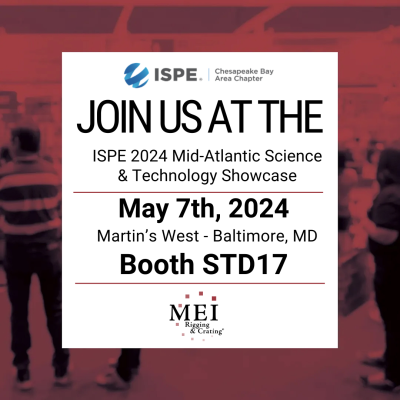

MEI Industrial Solutions Safety Program – Safe Rigging Services You Can Trust

At MEI, we have a strong safety culture underpinned by company-wide safety policies and procedures. MEI takes safety very seriously as evidenced by our EMR rating of 0.62. Our team is equipped with detailed procedures covering training and on the job safety and we have dedicated full-time Safety Managers in each of our 18 regional offices. We have won safety awards and recognitions from Microsoft, Turner Construction, JE Dunn Construction, IPS and others for our approach to on-the-job safety.

MEI Industrial Solutions Safety Training

MEI is accredited as a national training institute for NCCER and NCCCO. We are certified to perform training and certification for advanced rigging and advanced signal person. The MEI Learning Management System allows easy access to various training programs including OSHA 10 and OSHA 30 to all employees.

MEI Safety Program In Action

Our crews perform pre-task job hazard analysis (JHA) before commencing work. We have designated on-site safety managers for various projects, and we encourage all MEI employees to stop a job if they are concerned about safety. Site safety managers hold weekly site safety meetings and monthly all-hands safety meetings, conduct training, and undertake live project safety checks to ensure compliance with best practices. MEI also has an Incident Review Board responsible for reviewing all recordable incidents, facility damage occurrences, and “near miss” occurrences.

Partner With a Rigging Services Company Who Has a Strong Safety Program and Culture

Day in and day out our employees demonstrate their unwavering commitment to safety. We will always continue to be alert, aware, mindful, and well trained. We evaluate, plan, monitor and review every process we have in place. As safety needs evolve, so do we.

We are seeking individuals who value being a part of a company with a strong safety culture, as an Environmental Health & Safety Manager, your primary responsibility is to support the incident and injury free field operations of our regional locations and to promote the MEI culture of safety.